Kubuchwepheshe besimanje bokubonisa nge-elekthronikhi, ukuboniswa kwe-LED kusetshenziswa kabanzi kwizimpawu zedijithali, isizinda sesiteji, umhlobiso wangaphakathi kanye neminye imikhakha ngenxa yokukhanya kwayo okuphezulu, ukucaciswa okuphezulu, impilo ende nezinye izinzuzo. Ehlelweni lokukhiqiza lokuboniswa kwe-LED, ubuchwepheshe be-Encapsertion isixhumanisi esisemqoka. Phakathi kwabo, ubuchwepheshe be-SMD Encapbhinction kanye ne-COB Encapsolition Technology bangamakhambi amabili ajwayelekile. Ngakho-ke, umehluko muni phakathi kwabo? Le ndatshana izokunikeza ukuhlaziya okujulile.

1.Yiyini ubuchwepheshe bokupakisha be-SMD, umgomo wokupakisha we-SMD

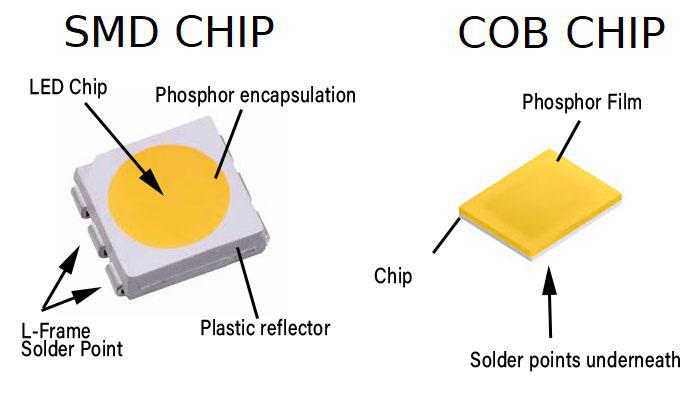

Iphakheji ye-SMD, igama eligcwele idivaysi efakwe endaweni ebekiwe (idivaysi ebekwe ebusweni), uhlobo lwezinto ze-elekthronikhi ezifakwe ngqo kwi-Prints Circuit Board (PCB) ubuchwepheshe bokupakisha komhlaba ophrintiwe (PCB). Lobu buchwepheshe ngomshini wokufakwa okunembile, i-chip eholwa nge-ebodsoted Ubuchwepheshe benza izakhi ze-elekthronikhi zibe zincanyana, zilula ngesisindo, futhi zilungele ukuklanywa kwemikhiqizo enemikhiqizo e-compact futhi engasindi.

2.Izinzuzo kanye nobubi bobuchwepheshe bokupakisha be-SMD

2.1 SMD PackAging Technology Accountageges

(1)Ubukhulu obuncane, isisindo esikhanyayo:Izakhi zokupakisha ze-SMD zincane ngosayizi, kulula ukuhlanganisa ubuningi obuphezulu, ezilungele ukwakheka kwemikhiqizo ye-miniaturized and lightweight ye-elekthronikhi.

(2)Izici ezinhle zemvamisa ephezulu:Izikhonkwane ezimfushane nezindlela zokuxhumana ezifushane zisiza ukunciphisa ukwehla nokumelana, ukuthuthukisa ukusebenza okuvame kakhulu.

(3)Ilula ukukhiqizwa okuzenzakalelayo:Ilungele ukukhiqizwa komshini wokubekwa okuzenzakalelayo, yenza ngcono ukusebenza kahle kokukhiqiza kanye nokuqina kwekhwalithi.

(4)Ukusebenza okuhle okushisayo:Xhumana ngqo ne-PCB Surce, lungisa ukuyeka ukushisa.

2.2 SMD Packaging Technology Ububi

(1)Ukulungiswa okuyinkimbinkimbi: Yize indlela yokugquma ingaphezulu komhlaba yenza kube lula ukulungisa futhi kube lula ukufaka izakhi, kepha esimweni sokuhlanganiswa okuphezulu, ukufakwa kwezinto ngazinye kungahle kube yinqwaba.

(2)Indawo ekhawulelwe yokuhlanza ukushisa:Kakhulu ngokusebenzisa i-pad kanye ne-gel ukushisa ukushisa, umsebenzi wesikhathi eside wesikhathi esiphezulu ungahle uhole ukugxila kokushisa, okuthinta impilo yenkonzo.

3.Yini ubuchwepheshe bokupakisha we-COB, umgomo wokupakisha we-COB

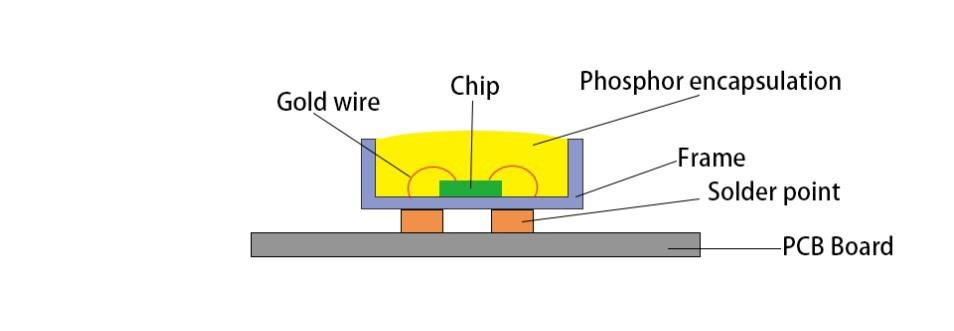

I-Cob Package, eyaziwa ngokuthi i-chip ebhodini (chip ephaketheni lebhodi), i-chip engenalutho ifakwe kubuchwepheshe bokupaka kwe-PCB. Inqubo ethile yi-chip e-chip (umzimba we-chip kanye nama-terminals ekristalu ngenhla) nge-pcb noma i-adhesive anamathela ku-PCB, bese kuthi nge-aluminium noma ngocingo lwegolide) ku-ultrasonic, ngaphansi kwesenzo Engcindezi yokushisa, ama-terminals we-chip i / o / o namaphaphu we-PCB axhunyiwe, futhi ekugcineni avalwe ngokuvikelwa kokuhlehlisa. Le nsizakalo isusa izinyathelo ze-LED ze-LED bead bead bead, okwenza iphakethe lihlangene kakhulu.

Izinzuzo ze-4.Izinzuzo nobubi be-Cob Packal Technology

I-4.1 COB Packag FACKOW TOUNTAGENT

(1) Iphakethe elihlanganisiwe, usayizi omncane:Ukuqeda izikhonkwane ezingezansi, ukufeza usayizi omncane wephakeji.

(2) Ukusebenza Okuphakeme:I-wire yegolide exhuma i-chip kanye nebhodi yokujikeleza, ibanga lokuhambisa lesiginali lifushane, linciphisa i-crosstalk kanye nokwenza izingqinamba nezinye izindaba ukwenza ngcono ukusebenza.

(3) Ukuchithwa kokushisa okuhle:I-chip ifakwe ngqo kwi-PCB, futhi ukushisa kudilizwe lonke ibhodi le-PCB, futhi ukushisa kudilizwa kalula.

(4) Ukusebenza Okuqinile Ukuvikelwa:Idizayini ebiyelwe ngokuphelele, enokungenzi manzi, umswakama-ubufakazi, ubufakazi bothuli, i-anti-tuli kanye neminye imisebenzi yokuvikela.

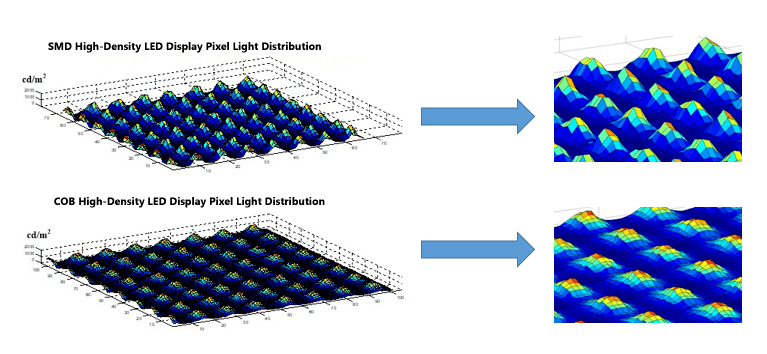

(5) Okuhlangenwe nakho okuhle kokubukwa:Njengomthombo wokukhanya ongaphezulu, ukusebenza kombala kucace bha, imininingwane emihle kakhulu, efanelekile ukubuka okusondele kakhulu.

I-4.2 COB PacAGN Technology Ubunzima

(1) Ubunzima besondlo:I-Chip ne-PCB Direct Welding, ayinakuhlukaniswa ngokwahlukana noma ukufaka esikhundleni se-chip, izindleko zokulungisa ziphezulu.

(2) Izidingo eziqinile zokukhiqiza:Inqubo yokupakisha yezidingo zezemvelo iphakeme kakhulu, ayivumeli uthuli, ugesi ozovumayo nezinye izinto zokungcola.

5. Umehluko phakathi kobuchwepheshe bokupakisha we-SMD kanye ne-COB PacAGging Technology

Ubuchwepheshe be-SMD Encopsertion nobuchwepheshe be-COB Encopsertion emkhakheni we-LED Display ngayinye inezici zayo ezihlukile, umehluko phakathi kwazo kuboniswa ikakhulukazi ekusebenzeni kwe-acbop, usayizi nesisindo, ukulungiswa kwezimo kanye nezimo zokulungiswa kanye nezimo zokulungiswa. Okulandelayo ukuqhathanisa okuningiliziwe nokuhlaziywa:

5.1 Indlela yokupakisha

Ubuchwepheshe bokupakisha be-⑴SMD: Igama eligcwele liyidivayisi ebekwe ebusweni, okungubuchwepheshe bokufaka ama-chip aphoqelele i-chip ehlanganisiwe ebhodini lesekethe eliphrintiwe (PCB) ngomshini we-patch ophrintiwe. Le ndlela idinga ukuthi i-Chip ye-LED ifakwe kusengaphambili ukwakha ingxenye ezimele bese ifakwa kwi-PCB.

I-⑵COB Ukupakisha Ubuchwepheshe: Igama eligcwele liyi-chip ebhodini, okungubuchwepheshe bokupakisha obhekene ngqo namadepho amasosha angenayo chip kwi-PCB. Kuqeda izinyathelo zokupakisha zobuhlalu be-LED yendabuko yendabuko, ngokuqondile bahlanganisa i-chip ebambekayo kwi-PCB nge-PCB nge-glue ephaselayo noma eshisayo, futhi ibona ukuxhumana ngogesi ngocingo lwensimbi.

5.2 ubukhulu nesisindo

Ukupakishwa kwe-⑴smd: Yize izakhi zincane ngosayizi, usayizi nesisindo sazo kusakhawulelwe ngenxa yesakhiwo sokupakisha nezidingo zePad.

Iphakethe le-⑵COB: Ngenxa yokushiywa kwezikhonkwane ezingezansi kanye ne-package Shell, i-Cob Page ifinyelela ukuhlangana okwedlulele ngokwengeziwe, okwenza iphakethe lincane futhi libe lula.

5.3 Ukusebenza kokushisa kokushisa

Ukupakishwa kwe-⑴smd: ikakhulukazi kuqeda ukushisa ngamaphaphu nama-colloids, futhi indawo yokuhlanza ukushisa ilinganiselwe. Ngaphansi kokukhanya okuphezulu kanye nezimo zomthwalo ophakeme, ukushisa kungagxila endaweni ye-chip, okuthinta impilo nokuqina kwesibonisi.

Iphakethe le-⑵COB: I-chip ifakwe ngqo kwi-PCB futhi ukushisa kungahlakazwa ngako yonke ibhodi ye-PCB. Lo mklamo uthuthukisa kakhulu ukusebenza kokuhlanza kokushisa kwesibonisi futhi wehlise izinga lokuhluleka ngenxa yokushisa ngokweqile.

5.4 lula ukugcinwa

Ukupakishwa kwe-⑴smd: Njengoba izakhi zifakwa ngokuzimela kwi-PCB, kulula kakhulu ukufaka indawo eyodwa ngesikhathi sokulungiswa. Lokhu kuyasiza ekunciphiseni izindleko zokulungiswa kanye nokunciphisa isikhathi sokulungisa.

I-⑵COB Ukupakisha: Njengoba i-chip ne-PCB zibhalwe ngokuqondile ziphelele, akunakwenzeka ukuqaqa noma ukufaka i-chip ngokwahlukana. Lapho kwenzeka iphutha, kuvame ukudingekile ukufaka esikhundleni sonke ibhodi le-PCB noma liyibuyisele efektri ukulungisa, okukhulisa izindleko nobunzima bokulungiswa.

5.5 Izimo zesicelo

Ukupakishwa kwe-⑴smd: Ngenxa yokuvuthwa kwayo okuphezulu nezindleko zokukhiqiza eziphansi, kusetshenziswa kabanzi emakethe, ikakhulukazi kumaphrojekthi abucayi futhi adinga lula ukulungiswa kwamabhodi angaphandle nezindonga zangaphandle ze-TV.

Ukupakishwa kwe-⑵Cob: Ngenxa yokusebenza kwayo okuphezulu nokuvikelwa okuphezulu, kulungele kakhulu izikrini zokubonisa eziphakemeyo zasendlini, ukuboniswa komphakathi, amakamelo okuqapha nezinye izigcawu nezidingo eziyinkimbinkimbi. Isibonelo, ezikhungweni zemiyalo, ama-studio, izikhungo ezinkulu zokuhambisa kanye nezinye izindawo lapho abasebenzi babuke isikrini isikhathi eside, ubuchwepheshe bokupakisha be-COB bunganikeza ngesipiliyoni esibonakalayo esibucayi futhi esifanayo.

Ukugcina

Ubuchwepheshe bokupakisha be-SMD kanye ne-COB Packag Technology ngayinye inezinzuzo zayo ezihlukile kanye nezimo zohlelo lokusebenza emkhakheni wezikrini zokubonisa. Abasebenzisi kufanele balinganise futhi bakhethe ngokuya ngezidingo zangempela lapho bekhetha.

Ubuchwepheshe bokupakisha we-SMD kanye nobuchwepheshe bokupakisha we-COB banezinzuzo zabo. Ubuchwepheshe bokupakisha be-SMD busetshenziswa kabanzi emakethe ngenxa yokuvuthwa kwalo okuphezulu nezindleko zokukhiqiza eziphansi, ikakhulukazi kumaphrojekthi abucayi futhi adinga lula ukulungiswa okuphezulu. Ngokwesinye ubuchwepheshe be-COB Packaging, ngakolunye uhlangothi, ukuncintisana okuqinile ezikrinini zokubonisa eziphakeme kakhulu zakwa-Indoor Display, amakamelo okuqapha kanye nezinye izinkambu ngokupakishwa kwayo okuhlangene, ukusebenza okuhle kokushisa kanye nokusebenza kokuvikelwa okuqinile.

Isikhathi sePosi: Sep-20-2024