Izindleko zokuthengwa kwezimpahla zesikrini se-LED ziphezulu kakhulu, ngaphezu kwesigidi noma isigidi esiningi se-RMB. Abakwa-LeaseHolders babuyela emuva ngokushesha ngangokunokwenzeka ukuze babambe iqhaza emisebenzini eminingi ukuthola izindleko, ngenkathi bezama ukunweba impilo yenkonzo yesikrini, ukuze isikrini sikhiqize imali eningi.

Ungasigcina kanjani isikrini sokuqasha esigabeni se-LED

1. Ukulawula okushisa

A Isibonisi Somlando SokuboniswaIhlanganiswe ikakhulukazi ebhodini lokulawula, ukushintshanisa amandla okuthola amandla, amadivaysi akhanyisekayo, njll., Futhi ukuqina kanye nokuqina kwazo zonke lezi zinto zihlobene kakhulu nokushisa okusebenzayo. Uma izinga lokushisa langempela lidlula uhla olucacisiwe lokusebenzisa umkhiqizo, hhayi impilo yalo kuphela oluzofinyezwa, umkhiqizo ngokwawo uzolimala kakhulu.

2. Ukusongelwa kothuli akufanele kunganakwa

Esimweni esinothuli, ngenxa ye-PCB adsorption yothuli, futhi ukufakwa kothuli kuzothinta ukuhlukaniswa kokushisa kwezinto zokushisa nge-elekthronikhi, kuzoholela ekukhuphukeni kwezinga lokushisa lezakhi, bese kuba nokwehla kokuqina okushisayo noma kukhiqize ukuvuza, okungaholela ekushisekeni okukhulu. Uthuli luzophinde lumunge umswakama, ngaleyo ndlela luhlasele umjikelezo we-elekthronikhi, okuphumela kwabanye akulula ukuphenya inkinga yesekethe. Ngakho-ke, unake ukugcina studio Hlanza, Gwema uthuli, lungiselela kusengaphambili.

3. Ukulungiswa ngenkuthalo

Ukuboniswa kwe-LED njalo lapho uqeda ukusebenzisa, lonke ibhokisi lisulwe lihlanzekile, kungenzeka libe yizindawo ezibucayi zihlanganiswe namafutha asetshenzisiwe. Ngakho-ke iminyaka embalwa phansi isibonisi iyaqinisekiswa futhi icishe ibe yintsha.

4. Abakhi beLed Plaject Equipment Equidlwation yolwazi alwanele.

Lezi zimo ziholele ekubonisweni endaweni yesigameko kwakuwukulayisha udlame nokulayisha, ukuthutha kanye nokwakha amakona amakhona agqamile, noma amakona amaskandi uma kuqhume. Kunconywe ukuthi imisebenzi akuyona isikhathi esiningi sokuqinisa ukuqeqeshwa kwabasebenzi, yenza ngcono ulwazi lokufunda kwabasebenzi kanye nokusebenza kahle kwemisebenzi eyakhiwe.

Ngaphezu kwalokho, abakhiqizi bangathuthukisa isikhathi sokuqasha isiqinisekiso, bathathe isinyathelo kuqala sokuvakashela ukugcinwa nokulungisa, baqeqeshe opharetha bekhasimende ukuthi bahlabelele kanjani futhi balungise isikrini. Ngisho nasezimweni ngazinye ukuhlinzeka ngokubuya efektri ukulungisa nokulungisa.

Amaphuzu asemqoka wokuthenga izikrini zokuqasha zesigaba se-LED

1. Ukuphepha komkhiqizo nokumelana nomonakalo

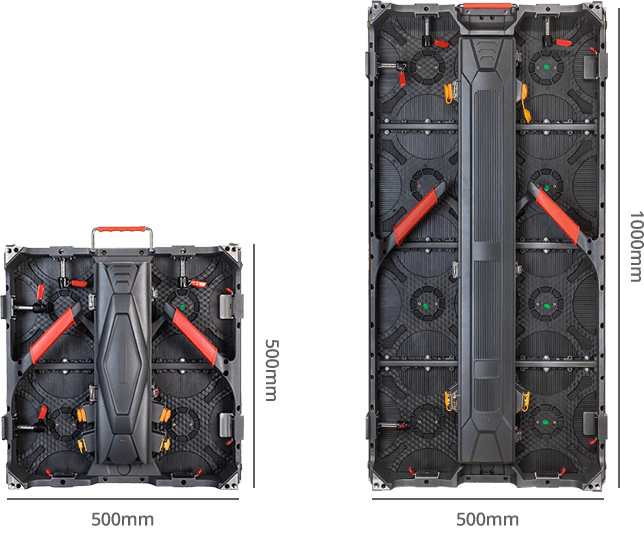

Ngendawo yokufaka yezikrini eziqashisayo, izikrini eziholwayo zifakwe ekufakweni okulengisweni noma ukufakwa kokufaka. Lezi zindlela ezimbili zokufaka zinezidingo eziphakeme zesisindo nokuphepha kwezikrini eziqashisayo. Ngoba izikrini eziqashisayo zidinga ukufakwa ezimboniswe kakhulu futhi zikhuphukele, izikrini zokuqasha kumele zibe mncane futhi zikhanye, futhi ukuxhumana kumele kube okuqinile, okuthembekile kufanele kube lula ukugwema izinsongo ezingaba khona kubasebenzi abasendaweni.

Izikrini eziqashisayo ze-LED zivame ukususelwa ukuthuthwa ngemoto, umkhumbi noma indiza. Ngesikhathi sokuhamba, imiphetho namakhona ezikrini eziqashisayo kungahle kufakwe amaqhubu ngenxa yamaqhubu, kepha ukuze kungathinti umphumela wokusetshenziswa, izikrini eziqashisayo kumele zinciphise ukulimala kwezinto ezenziwe nge-elekthronikhi ezibangelwa Ngokuhamba, ukuze kungathinti umsebenzi ojwayelekile wokubonisa.

2. Ukufakwa okulula nokuhlukaniswa

Ukuze uqinisekise ukuphepha nokusetshenziswa okujwayelekile kwezikrini zokuqasha, izikrini zokuqasha ngokuvamile zidinga ukufakwa ngeqembu lokufaka lokufaka isibonisi, kepha lokhu kuzonyusa izindleko zesabelomali sekhasimende. Ngakho-ke, abakhiqizi kufanele baklame imikhiqizo ngokombono wokufakwa okulula nokuhlukaniswa, ukuze ama-General Invals angahlangana kalula futhi anciphise izikrini zokuqasha, futhi athuthukise ukusebenza kahle kwamakhasimende.

3. Ukubuyiselwa okusheshayo nokulungiswa

Lapho isikrini sokuqasha sinokuhluleka kokubonisa kwendawo, isikrini sokuqasha esiholayo se-LED kumele sikhishwe ngokwengxenye futhi sithathelwe indawo, futhi kufanele sithathelwe indawo ngokushesha ukuze siqinisekise ukuthi ukusebenza kuyinto evamile.

4. Uhlelo lokulawula kulula ukuqala

Ngokuhlanganiswa kokufakwa, i-ejenti yokuqashisa ukuhlinzeka nge-Professional Control System Instration Instration Manual, imishini yokufaka kufanele futhi ikhombise imininingwane yokuholwa, okulula kubasebenzi ukukhomba izakhi kanye nokufaka i-oda, ukuvikela inqubekela phambili yeisikrini esiqashisayo

Isikhathi sePosi: Aug-08-2024